Why Drum Motors?

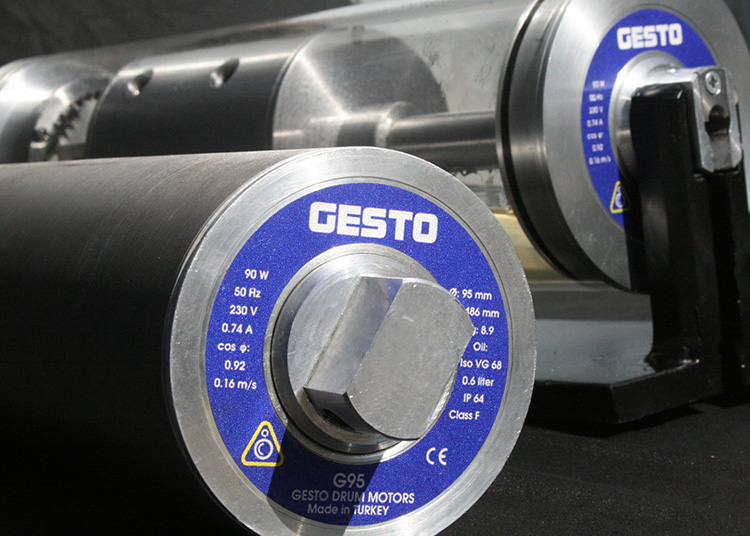

Drum motors ,that have been used in various sectors in material handling industry since 1950 worldwide, are high efficent, maintanence free, usable for even most harsh environments, easy to install, compact, clean and trustworthy equipments. With its broad product range, this system has been designed according to the material handling industry needs, to work continously -7 days a week, 24 hours a day-.

Coal and Lignite Mines, Iron-Steel Facilities, Mining Facilities, Powerplants, Batch Plants, Asphalt Plants, Recycling Facilities, Cement Plants, Stone Crushing and Screening Facilities, Tunneling Plants, Seaports, Airports, Supermarkets, X-Ray Security Systems, Food Industry, Pharmaceutical Industry, Salt-Fertilizer-Feedstuff Industry, Fish-Meat-Chicken Handling Facilities, Sugar Factories, Chemical Industry, Electircal Industry, Automotive Industry, Packaging Facilities, Logistics and Postal Applications etc...

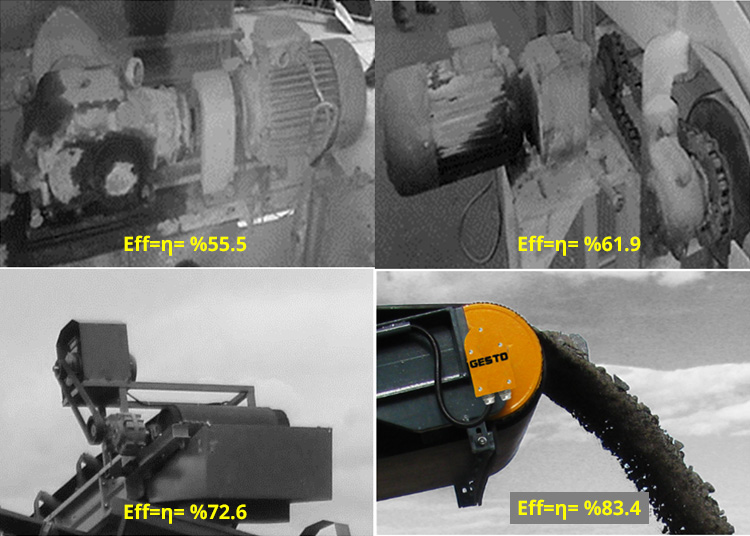

HIGH ENERGY EFFICIENCY

In conventional multi component drive systems, conveyor drive is made by 3 different methods.

When compared with those three, it provides an energy cost saving of 4,100 dollars per year. (for 5.5 kW sample motor), GESTO drum motor demonstrates its extreme superiority. More...

MAINTENANCE FREE

Gesto drum motor are -install and forget- type drive systems and do need almost zero maintenance. In conventional drive system there are various moving parts such as chain, belt, bearing housings demanding periodical maintenance and adjustments. However Gesto drum motors consist of only a closed main drum and two fixing brackets. Decrease in failure and maintenance time bring Gesto costumers low operation costs and high productivity.

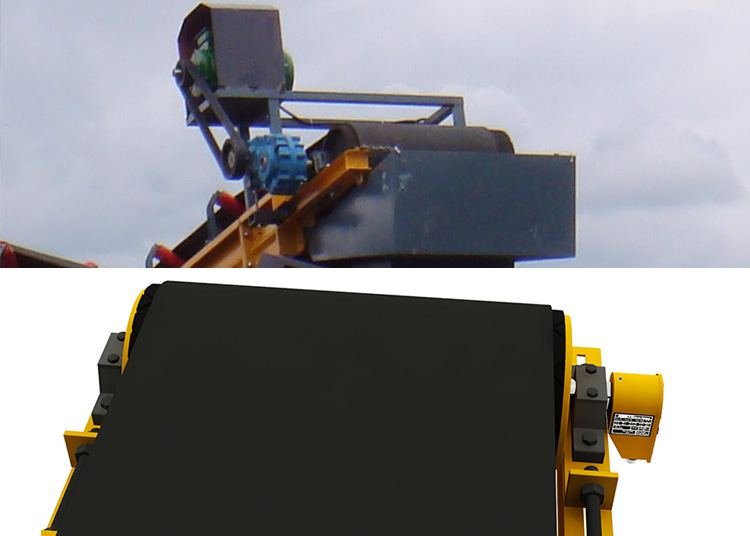

LOW INSTALLATION COSTS AND SPACE SAVING

Gesto drum motors contain fewer installation parts compared with classical multi equipment drive systems. Thus its assembly to the conveyor structure is more simpler, faster and more practical. These facts lead to five times decrease in assembly costs both for end users and OEMs. More...

Gesto takes up significantly less space compared with the conventional drive systems just because all drive units are in the drum shell. More...

DURABILITY

Because all moving parts and drive mechanism are isolated in the drum, Gesto is not affected by harsh environmental conditions including oil, water, grease, chemicals, dust and sand. Regardless of any hard conditions Gesto operates with 100% performance.

SAFETY

In terms of safety, the risky moving external parts need periodical and frequent maintenance. Totally enclosed structure and its almost maintenance-free design make Gesto the safest conveyor drive in the world.

CLEANLINESS AND HYGIENIC

In conventional drive system throughout handling, usage of external parts such as belt and chain, is the main factor which contaminates the food, electrical components, plastic, glass etc... which normally have to be clean steadily. Gesto, with its totally enclosed and isolated (IP66) drive system and stainless steel products when requested, eliminates contamination risks.

ESTHETIC DESIGN

Due to the fact that motor, gearbox and bearings are isolated in the drum shell and having a compact structure, Gesto drum motors look remarkably esthetic.

In various application fields, standard Gesto drum motors can be manufactured in a wide range of products with different power, speed, length-diameter options, with carbon/stainless steels shafts, lagged/unlagged drum, brake/brakeless variations etc..